Additive Manufacturing replaces numerous traditional manufacturing processes, facilitates the development of new products and business models and helps establish new value-added and supply chains. Are these claims about the possibilities of Additive Manufacturing real, and in which industries have they already been successfully implemented? What is really feasible, to what extent are businesses already using 3D printing, and what is the driving force behind this development? AM Solutions shines a light on these and other interesting questions in its six-part live event series “inside AM”. In this series, representatives from renowned companies, active in different industrial sectors, will provide a valuable behind the scenes glimpse and report about their experience, applications, visions and obstacles that must be overcome.

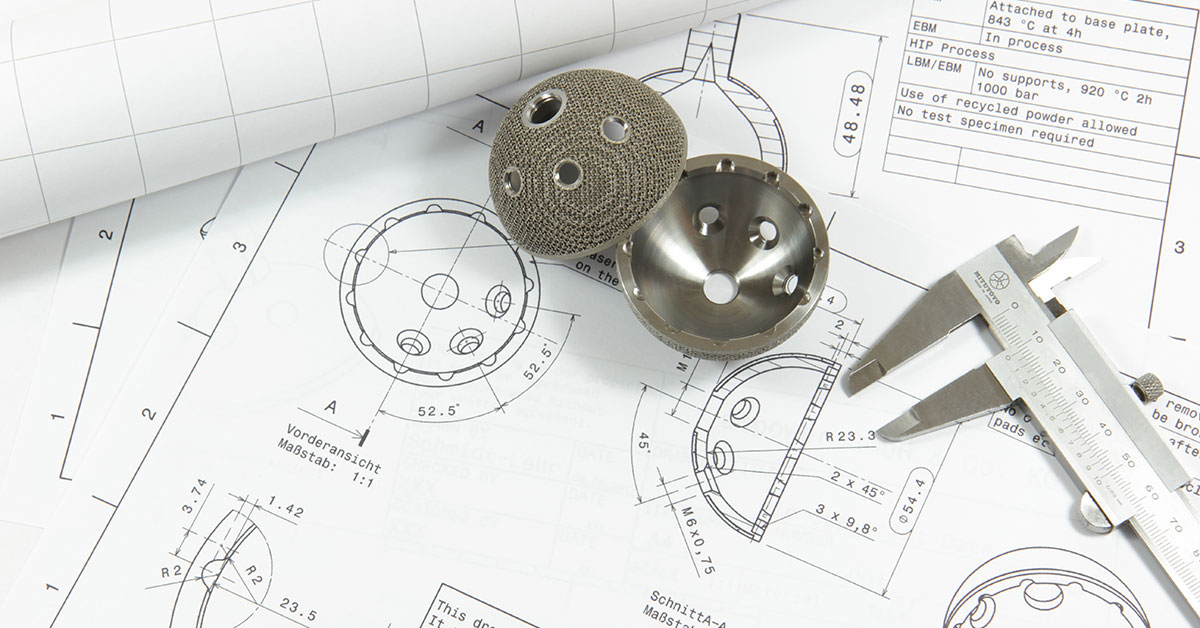

Design freedom, light-weight construction, efficient resource utilization, cost and time savings, these are some of the keywords that are frequently expressed in conjunction with Additive Manufacturing (AM). Add to this the potential effects on established logistical systems, the need for personnel to drop traditional engineering philosophies and the potential to individualize products and adapting them to the wishes and requirements of the consumers to an extent, so far thought impossible. Does this mean that Additive Manufacturing is changing the world? Are these things really true, and what is the actual situation in the field of AM? How, and in which industries, are 3D printing technologies already used? And what is still just a vision? With its new interactive live series “inside AM” AM Solutions – 3D post processing technology, a brand of the Rösler Group that specializes on 3D post processing solutions, will answer many of your questions. It provides not only valuable information for the actual users of the 3D printing method but also for anybody interested in new technologies.

Interactive platform that offers valuable behind the scenes information

The live-streams are conducted in English and are accessible from anywhere in the world. Representatives from renowned companies, active in such diverse industries as medical engineering, aerospace, energy, automotive/motor sports and consumer products, will report about their experience with AM and will highlight the various aspects of this new manufacturing technology. Under the moderation of Georg Schöpf, editor-in-chief of a well-known AM magazine, the participants will provide valuable behind the scenes insights and will report on the actual status of Additive Manufacturing in their respective industrial sector and company. The interactive format of this event allows viewers from all over the world to participate in the conversation and pose their questions live to the respective participants. The event is broadcast live from the new Customer Experience Center of AM Solutions. Manuel Laux, Head of AM Solutions – 3D post processing technology, explains: „Anybody, who deals with the subject Additive Manufacturing, is probably overwhelmed by reports about the numerous innovative applications of this technology. With our interesting interactive event, we, jointly with our guests, want to shine a light on the question ‘Additive Manufacturing changes the world. Is this just a vision or already real?’ and provide information on the actual situation”.

Formula One and Sauber Engineering in the pole position

Guest at our first event is Christoph Hansen, Director Technology & Innovation at Sauber Engineering AG, a member of the Swiss Sauber Group. Internationally, this company is not only known through the Sauber-operated Formula One team, Alfa Romeo Racing ORLEN. The origins of the company stem from the demand to make racing cars faster, lighter and more reliable. Sauber tackled these challenging problems with Additive Manufacturing and, today, can be truly called a pioneer in this field. Christoph Hansen comments: „When AM Solutions presented this new discussion concept to me, I immediately liked the idea to look at Additive Manufacturing from different angles and from the view of different industries. It is honest and informative. I look forward to report to the viewers, how we started exploring the possibilities of AM, and how we expanded the use of this manufacturing technology beyond just the Formula One racing cars”.

The live stream with Christoph Hansen will be broadcast on Wednesday, June 9, 2021 at 3.00 PM (CET). Viewers can register free-of-charge under www.inside-am.com. The subsequent online live events will take place once per month. Exact dates and time will be communicated in due time. For the time being the participants of the next events are still kept a secret by the event organizers.