In the dynamic world of Additive Manufacturing, innovation is not just about pushing boundaries; it’s about shaping the future of industries like never before. For years, AM’s narrative centred on application-driven approaches and enhancing efficiency across sectors. Yet, the true essence lies in smart utilization, achieving more with less. In a significant stride towards meeting the strict requirements of the railway sector, Siemens Mobility and LEHVOSS – Customized Polymer Materials have released a groundbreaking development: LUVOSINT PPS 9268 BK, a cutting-edge SLS powder with the highest flame retardancy according to the EN 45545-2 standard, tailored for sustainable and cost-efficient production across industries such as railway, aerospace, and automotive.

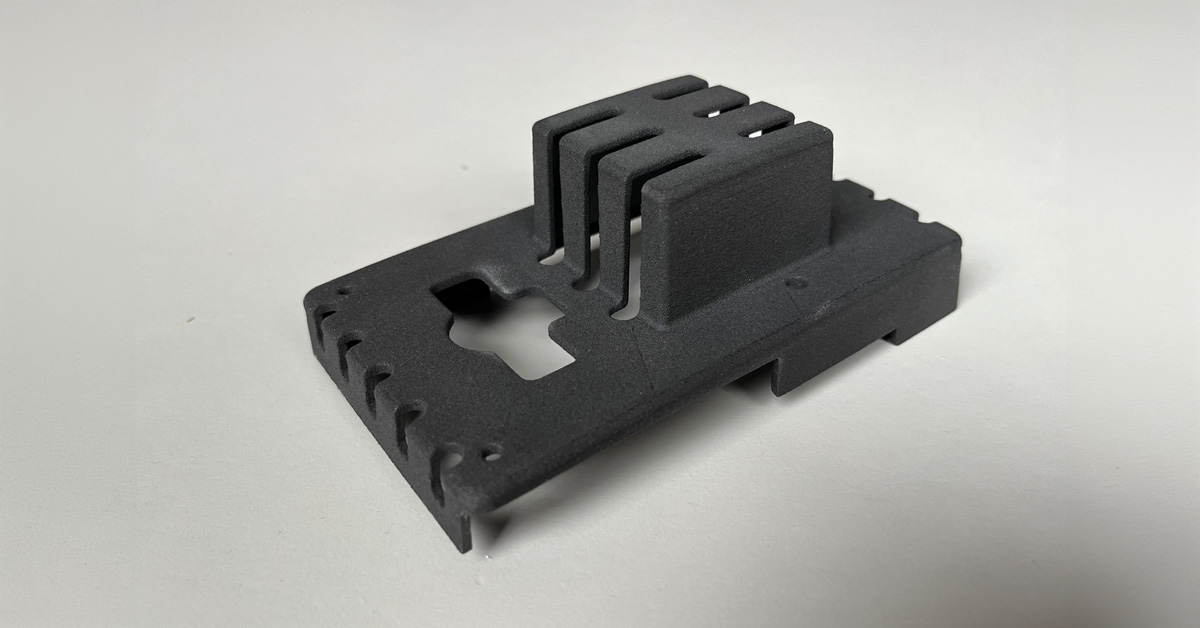

Presented by Dr Stefan Landkammer at the AM Forum 2024 in Berlin, LUVOSINT PPS 9268 BK marks a significant advancement in 3D printing technology. With Level R1 HL3 flame retardancy rating certification—the first of its kind in the market—this powder sets a new benchmark for safety and reliability, particularly in railway applications. Unlike conventional filament-based materials, LUVOSINT PPS 9268 BK offers unmatched versatility and performance, making it suitable for a wide range of polymer components, including large interior and exterior railway parts.

The development of LUVOSINT PPS 9268 BK underscores the power of collaboration and industry initiatives in addressing critical needs. Discussions within the MGA Materials Working Group played a role in identifying the spread demand for such material, emphasizing the importance of collective efforts in driving innovation. With its inherent flame-retardant properties and 100% reusability, LUVOSINT PPS 9268 BK presents sustainable and cost-effective solutions for manufacturers, minimizing waste and maximizing efficiency.

This material presents various benefits across multiple domains. In terms of sustainability, its 0% waste rate ensures that all excess powder from previous production processes can be efficiently reused, eliminating the need for disposal within the powder cycle and significantly enhancing its cost-effectiveness and eco-friendly characteristics. Economically, LUVOSINT PPS 9268 BK offers competitive pricing, exceeding that of most flame-retardant filaments. Furthermore, its electrical properties are revolutionary. With outstanding dielectric strength, this powder offers remarkable opportunities for insulation applications, representing a substantial advancement in material technology.

In conclusion, the introduction of LUVOSINT PPS 9268 BK represents a significant milestone in the evolution of Additive Manufacturing. Through collaboration and innovation, this new material stands for progress and prosperity, shaping a more sustainable and efficient manufacturing landscape for years to come.