[vc_row][vc_column][vc_column_text]Berlin, 28 April 2020

MGA to hand over 5,000 face shields to Johanniter-Unfall-Hilfe tomorrow thanks to call-for-help

As announced within the recent initiative 3D Printing fights Corona, thousands of face shields from an appeal for help of the international network for industrial 3D printing MGA will be ceremonially handed over in front of the MGA office on Wednesday, 29 April 2020 at 16.00 hrs. Initiated by a concrete request of the Johanniter-Unfall-Hilfe, the network recently addressed its members and many other 3D printing companies to support in the acutely difficult procurement situation and to produce and donate face shields by means of additive manufacturing.[/vc_column_text][vc_single_image image=”2786″ img_size=”1000 x 667″ onclick=”custom_link” link=”https://medicalgoesadditive.org/request/johanniter-needs-5000-face-shields/”][vc_column_text]In the current pandemic, improvisation is vital in many areas, as usual purchasing channels are not always reliable and the supply sources at times have even dried up. The Johanniter-Unfall-Hilfe was hit hard by this situation, especially at its in-house trainings when preparing those providing daily care became critical. 3D printing, also known as additive manufacturing, provides an essential advantage here, as the products can be manufactured locally, fast and extremely flexibly.

Kevin Grigorian, Head of the Emergency Medical Services and Civil Protection Department at the Federal Headquarters of the Johanniter-Unfall-Hilfe is very pleased: “The 3D-printed shields will make an important contribution in preparing our volunteers in civil protection for special activities in the Corona pandemic. Certified protection material can thus be reserved for real emergencies. Indeed, the 3D-printed shields will allow the volunteers to practice the complex handling of protective equipment under live conditions. We thank the entire MGA network for the 5,000 face shields and for supporting us so quickly and flexibly”.

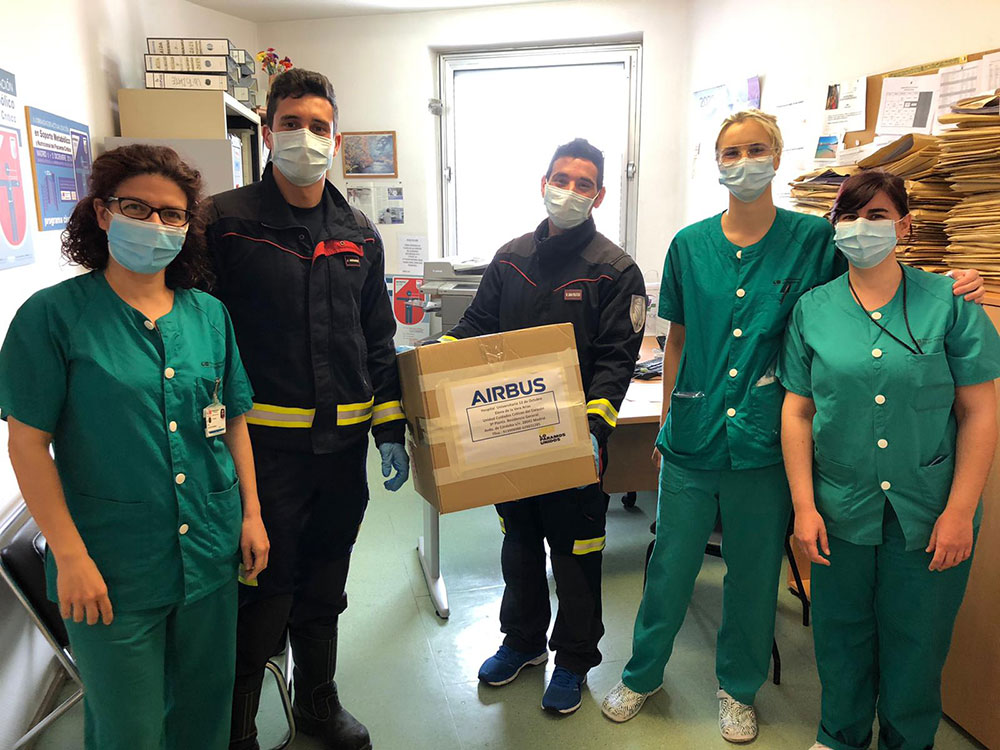

The drastic growth in demand is explained by the droplet transmission of the COVID-19 pathogen, for which reason extensive protective precautions must be taken when making contact with suspected cases and patients. The facial shields serve to cover the face and thus provide a further barrier to the highly infectious pathogen SARS-CoV-2 on top of mouth-nose protection.[/vc_column_text][vc_single_image image=”2782″ img_size=”1000 x 750″ onclick=”custom_link” link=”https://medicalgoesadditive.org/request/johanniter-needs-5000-face-shields/”][vc_column_text]MGA’s call-for-help led to assistance from printer manufacturers, 3D printing service providers and makerspaces. Almost 50 different producers took part in the appeal, bringing together some 5,000 face shields, which are now being used for the protection of more than 25,000 full-time and approximately 40,000 volunteer employees in almost 300 regional, district and local associations throughout Germany. Remarkable is the range of committed donors, from individuals, maker communities such as MakerVsVirus.org, 3D printer manufacturers such as igus® and EOS, research institutes such as the DMRC – Direct Manufacturing Research Center and the Fraunhofer Initiative Generative Fertigung to large corporations such as Airbus and Deutsche Bahn.

Donors: 3D Innova Tech UG, 3dk.berlin, 3Dmensionals.de, Airbus Customer Service Toulouse, Airbus Germany, Baker Hughes, Blue Production GmbH & Co. KG, Cadus e.V., Condor Group, Deutsche Bahn AG, DMRC, EOS GmbH, ERIKS Deutschland GmbH, EvoBus GmbH, Fraunhofer EMI, Fraunhofer IAPT, Fraunhofer IGCV, Fraunhofer IPA, Fraunhofer IPT, Fraunhofer IWU, Grohe AG, Hirschvogel Umformtechnik GmbH, Hochschule für angewandte Wissenschaften Coburg, igus GmbH, IT-Service Leipzig GmbH, Kegelmann Technik GmbH, Krause DiMaTec GmbH, Lehmann&Voss&Co. KG, Leichtbau-Zentrum Sachsen GmbH, Maker vs. Virus, Makerbot, Mobility goes Additive e.V., MotionLab Berlin, Netzwerk offener Werkstätten Brandenburg, PICCO’s 3D World, PRIMAX 3D, PVA Löt- und Werkstofftechnik GmbH, radotec GmbH, Satair A/S, Sauter Engineering + Design, Schönborner Armaturen GmbH, Schubert Additive Solutions GmbH, Stickerei Keinath GmbH, TEUFEL Prototypen GmbH, TU München, vi2parts, Vision Devices GmbH, voxeljet AG, xHain hack+makespace, ZAL Zentrum für Angewandte Luftfahrtforschung and many private donors.

The MGA initiative 3D Printing fights Corona is a virtual format in which experts from hospitals and the 3D printing industry exchange views on the latest developments, specify acute needs and showcase innovative approaches with 3D printing. Moreover, MGA established the website medicalgoesadditive.org with use cases, FAQs, helpful links and a newsroom that is specifically dedicated to the current pandemic.

For media clarification, please contact:

MGA Medical – a division of Mobility goes Additive e.V.

Contact: Susanne Merten, Marketing & PR Director

e: press@mobilitygoesadditive.com | t. +49 (0)30 757 66 111

[/vc_column_text][vc_column_text]

[/vc_column_text][/vc_column][/vc_row]