Anyone who has ever dealt with medical approval procedures knows the difficulties and mountains of questions and approval paths one is confronted with in this regard.

But no matter what you do, there is one thing you can’t avoid:

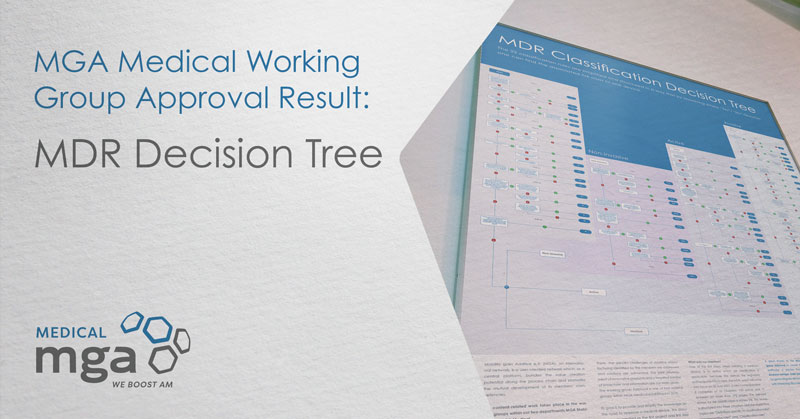

The Medical Device Regulation came into force on May 25, 2017, and is now finally applicable as of May 26, 2021. It comprises of 10 chapters, 123 articles and 17 Annexes, on more than 175 pages.

It is used for the risk classification of medical products, whereby the 22 classification rules from Annex VIII in particular must be observed. The MDR is formulated in comprehensive legal jargon and is difficult for non-specialists to understand and apply.

To break down this extensive construct, the experts from our Approval working group, lead by Simon Schlagintwelt (TÜV Süd Product Service GmbH) and Dr. Cora Lüders-Theuerkauf (Mobility goes Additive e.V.) have jointly developed a simplified procedure. The decision tree, which they have designed, is arranged in a clear structure, which guarantees an easy and quick orientation.

Here, the 22 classification rules are simplified and structured in a way that by answering simple “Yes”/” No”-Question one can find the associated risk to one’s device.

The user is being navigated through the questions automatically and arrives at a result by simply following the path.

It is available to MGA members free of charge in the internal members’ area of the MGA website as a PDF file. External interested parties can also purchase it, for more information please contact us directly at info@mga-net.com.