Despite all Corona odds, we made it!!! Our first ever hybrid event and certainly one of the last few opportunities for the AM community to physically meet eachother is over.

On 6 October 2020, Day 1 of our two-day hybrid event, we kicked-off with the General Assembly including the election of the Executive Board of MGA Mobility and MGA Medical (Mobility goes Additive e.V.).

The Executive Board was newly constituted and has been officially confirmed, now consisting of four board members again:

<strong>Gorden Falk</strong> from DB Heavy Maintenance (DB Fahrzeuginstandhaltung GmbH) was appointed as Chairman of the Board. Prof. Dr.-Ing. <strong>Claus Emmelmann</strong> remains as the Vice Chairman for MGA and also <strong>Johannes Emmelheinz</strong> has been confirmed as a member of the Board. Moreover, <strong>Güngör Kara</strong> from <strong>Ottobock</strong> was newly appointed, representing the Medical division of MGA.

The cash auditor <strong>Philip Janssen </strong>was discharged from his function. His position is now taken over by <strong>Karsten Reinhardt</strong>, Director Finance / Controlling at DB Fahrzeuginstandhaltung GmbH. Moreover, the financial budget for the financial year 2019/2020 of MGA Mobility goes Additive e.V. and the budget planning for the current financial year 2020/2021 were approved.

At 16.00 in the afternoon, the conference part – open for also non-members to attend – started with a brief Welcome address of the Executive Board Chairman Gorden Falk followed by a clear highlight: a keynote of <strong>COBOD International</strong> and <strong>PERI</strong> on concrete printing, presented by Henrik Lund-Nielsen and Dr. Fabian Meyer-Broetz.

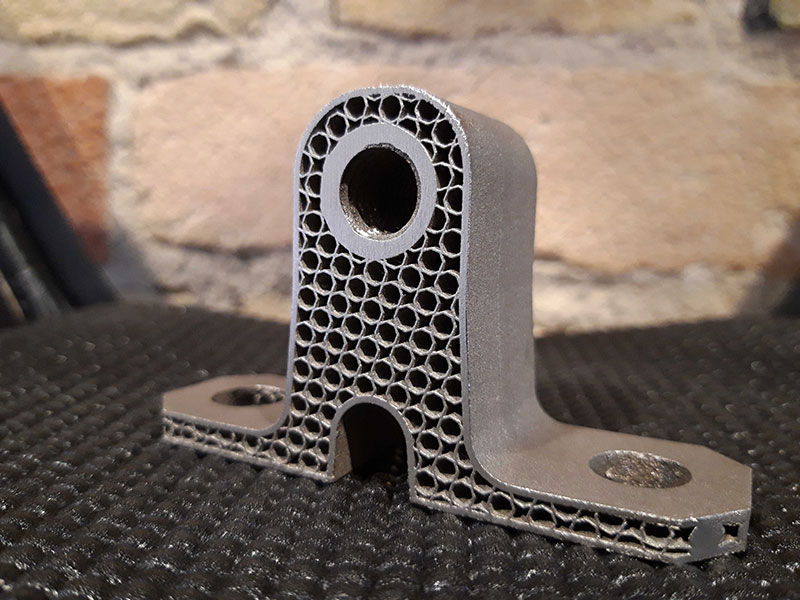

The later afternoon was used to present some outstanding working group results. Working group leaders and participants of the working groups <em>Approval in Rail, Ecological Sustainability, RAILiability, Education, MOBILITY | Materials</em> as well as of the<em> MGA MEDICAL</em> working groups gave a thrilling status report about their special and specific outcomes.

Public funding opportunities for AM were addressed by <strong>Werner Loscheider </strong>from the<strong> German Federal Ministry for Economics and Energy</strong> and <strong>David Hampel</strong> from our strong supporter <strong>Berlin Partner for Business and Technology</strong> spoke about the potential of Berlin as a Capital of Additive Manufacturing. The clear highlight of Day 1 was the opening of the newly installed IAM HUB Berlin here at the Marienpark.

Day 2 delivered several cross-industry presentations with great keynotes from <strong>EOS</strong>, <strong>KIND Hörgeräte</strong>, <strong>Siemens Mobility</strong>, the <strong>Dutch Navy</strong>, <strong>Autodesk</strong>, <strong>NedTrain</strong> and ended with a highlight: a panel discussion on “AM – where are you going?”.

Finally, we also introduced some new features of the MGA platform to you. Now, your perfect Marketing tool is ready: <a href=”http://www.weboostam.com”><strong>weboostAM.com</strong></a>, the MGA platform for your company portfolio, use cases as well as the newly installed category Technical Standards. Pimp your profile now and attract new 3d printing business!

The MGA AM2020 has been a great course and we thank everyone for joining in, whether in person on-site or virtually! With <u>160 attendees</u> it has been our most challenging, but also biggest MGA event ever!

In hopin, the tool of choice for virtual participation, we encountered <u>attendees from almost 15 countries of the world</u>, e.g. Germany, Hungary, Israel, the United Kingdom, Belgium, Sweden, France and even Japan. What fascinated us the most is how well the virtual experience obviously worked: on average, <u>one virtual participant spent 444 minutes in the video stream</u> on both days, which is an impressive more than 7 hours! Keeping people on the ball for so long is the greatest success for us!

Thanks also to our sponsors and supporters to make this event possible at this high level, namely <strong>Siemens Mobility</strong> and <strong>Autodesk</strong> as well as our partner <strong>Berlin Partner for Business and Technology</strong>.

A selection of photos is already online – to sneak in go to <a href=”https://mobilitygoesadditive.org/annual-meeting/impressions/”><u>impressions</u></a>. More documentation will follow online soon… so stay tuned!